Improving Production Quality with Machine Learning

Production defects can lead to dissatisfied customers at best and dangerous accidents at worst. It is in the interests of producers in all industries to reduce the amount, and severity of production errors. This task can be a difficult one however, with rigorous quality control procedures requiring extensive investment in staff and process management.

Recent developments in AI technology have shown the potential to streamline this important aspect of production. By exposing machine learning algorithms to thousands of annotated images of different products computer vision models are able to accurately and reliably detect defects that might be invisible to the human eye.

We will look at three industries that are benefiting from the continued development of this technology. We will show how, in each case, the services provided by annotation company Keymakr are ensuring that high quality datasets are available to sector innovators.

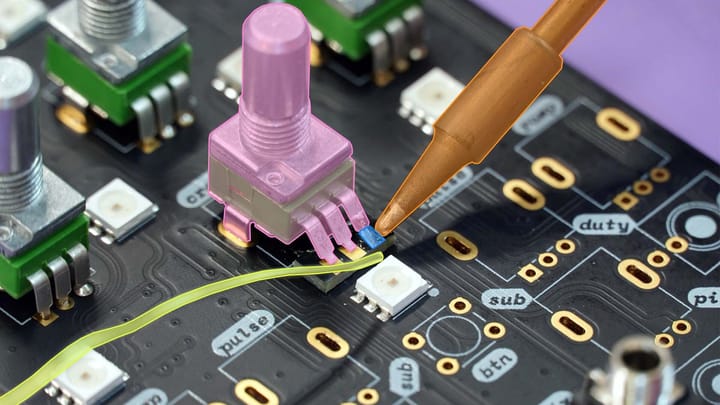

Detecting defective circuit boards

Errors in printed circuit boards can render a wide range of machines inoperative. The mass production of circuit boards is essential for a number of industries, so ensuring that anomalies are kept to a minimum is of the highest importance. Machine learning algorithms can be trained with annotated images of circuit boards, containing a representative sample of complete and defective examples. These systems can be integrated into the production process, allowing companies to save money and time, whilst producing maximally effective circuit boards.

Data security is essential when annotating data for circuit board inspection software. Images being labeled could contain sensitive information about proprietary technology. Keymakr guarantees data security by employing robust processes and countermeasures, including: secured offices, proprietary services, data expiration, and VPNs.

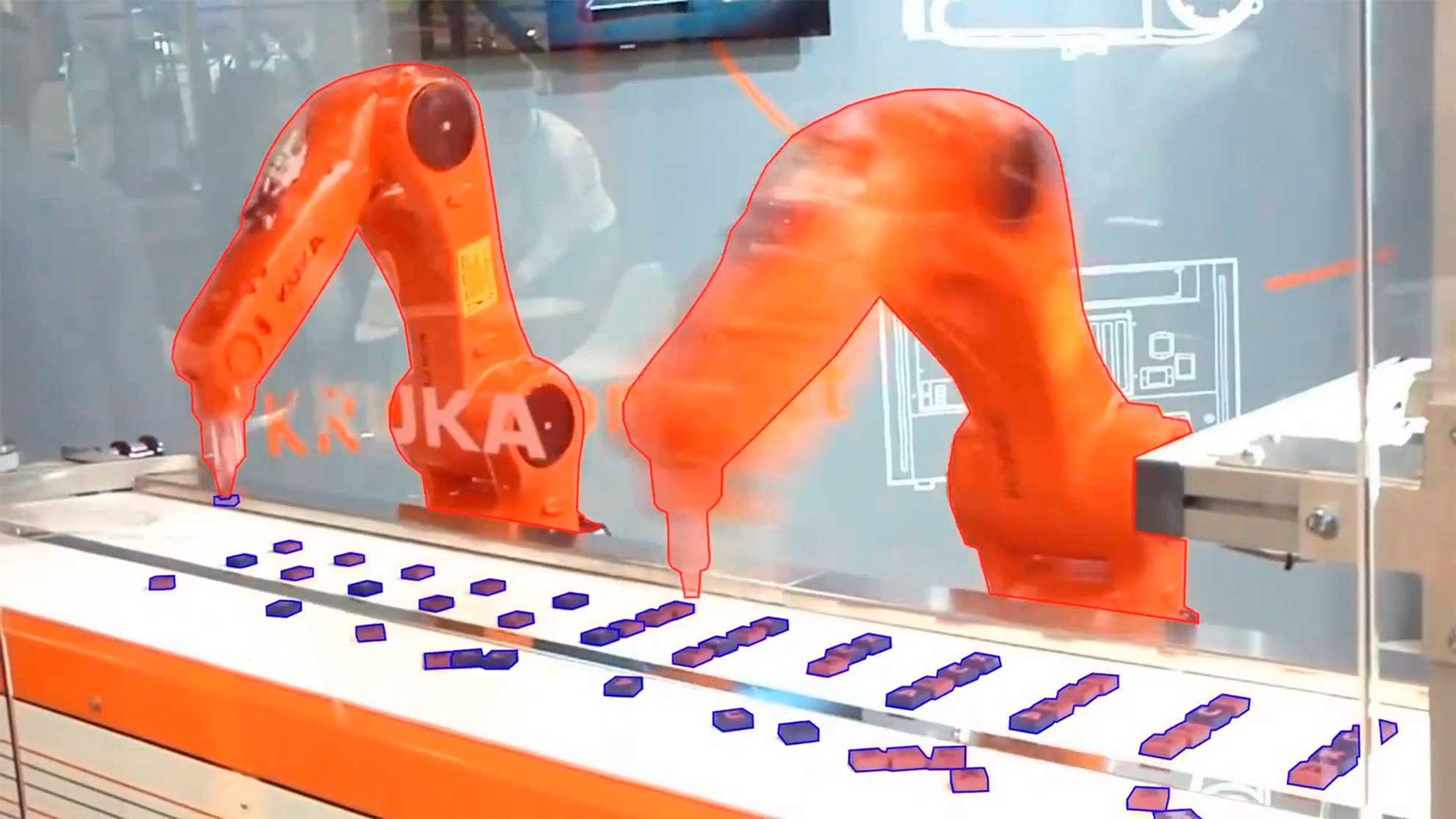

Automated quality inspection

The solar energy industry is expanding rapidly. As the efficiency of solar panels increases so does the demand for this important technology. For this success to continue reliability is crucial. Small defects, or micro cracks, in panel surfaces can significantly reduce energy production, and make the panels more susceptible to bad weather.

AI can be used to survey solar panel arrays before and after installation. Annotated training data allows machine learning models to spot these microscopic details that would be invisible to humans on the production line or during construction.

Semantic segmentation is an annotation technique that allows AI models to function in complex outdoor environments like a solar array. Annotators assign each pixel in an image to a given class, e.g. sky, solar panel, ground. This imbues training images with vital contextual information. Annotation providers, like Keymakr, are experts in semantic segmentation, removing the burden of dataset creation from busy developers.

Food and beverage monitoring

Ensuring that the highest standards of quality control are enforced is obviously highly important in the food and beverage industry. Anomalies and inconsistencies during production have the potential to endanger human health, and leave companies open to legal redress.

AI powered inspection systems are able to observe defects in packaging or in factory production, allowing operators to address recurring issues and take damaged products out of circulation.

When human health is at stake quality control in image annotation is essential. Keymakr uses three levels of human verification and an additional automated sense check to make sure that annotation errors do not make it into final datasets.

Annotation services ensure precision

In order to ensure quality with machine learning AI innovators require quality in image and video annotation. Keymakr’s experienced managers and skilled in-house annotation team have a track record of creating exceptionally precise annotations.