Bounding Box Annotation Supports AI Development in Manufacturing

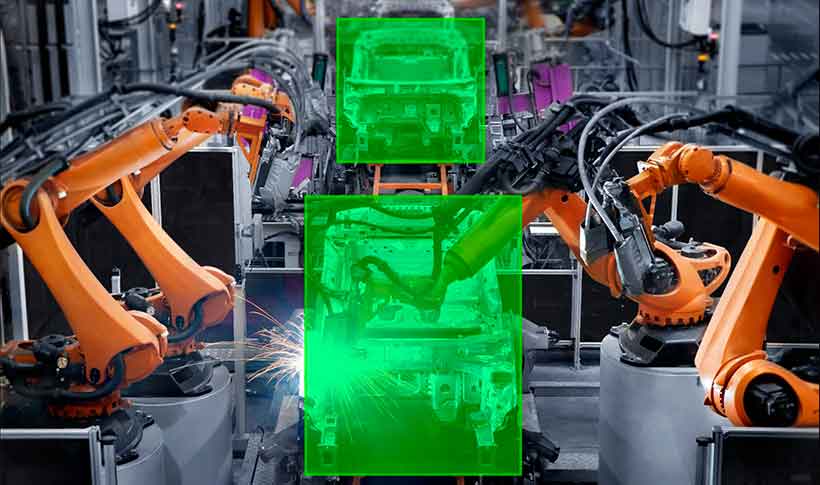

AI powered robotic devices could revolutionize manufacturing by increasing efficiency, reducing costly errors, and keeping humans safe. Once slow to adapt to digital innovations, the manufacturing sector is now embracing the potential of computer vision based AI models.

Machine learning enables AI systems to adapt to the, at times, chaotic environment of a busy production line. The raw material of machine learning for computer vision is annotated images and video. By adding information to images in the form of labels, human operators can create training sets that give models context and meaning.

This blog will examine one specific annotation technique that is central to robotics AI: bounding boxes. We will cover some of the use cases that are supported by bounding box annotation in this sector. Increasingly industry leaders are choosing to optimize their annotation process by outsourcing to annotation services like Keymakr.

Bounding box definition

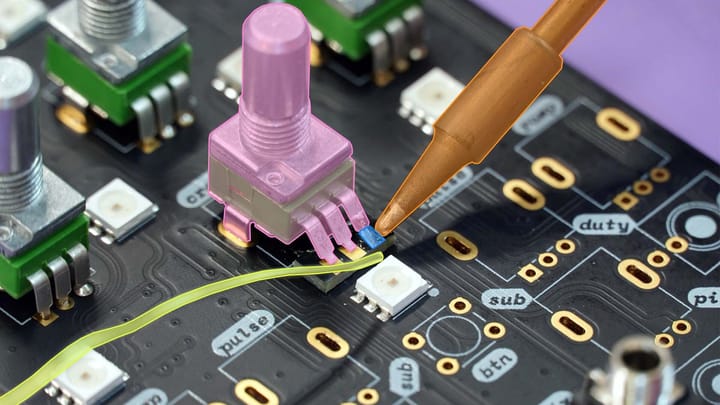

Bounding boxes are perhaps the most elementary form of image annotation. Using an annotation platform human annotators drag a box around a targeted, relevant object. The box is assigned a colour and a label according to the instructions of machine learning engineers. If video is being annotated, then target objects need to be boxed in each frame. The advantage of this technique is its speed, allowing annotators to locate objects at a much faster rate.

AI use cases in robotics and manufacturing

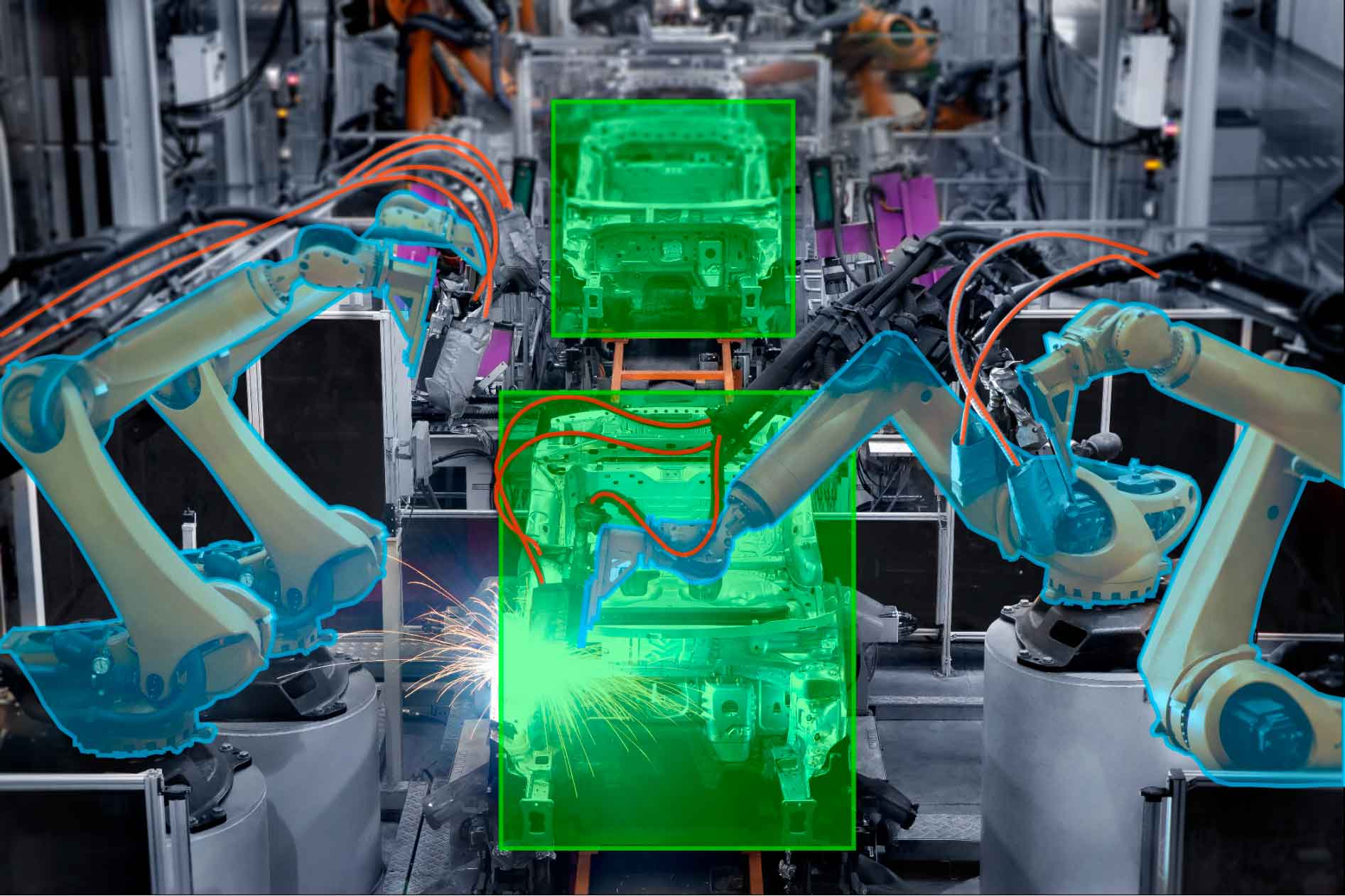

Bounding boxes locate relevant objects so that machine learning algorithms can iterate, and learn to identify them in real time. This important annotation practice is at the core of the models that drive the following manufacturing applications:

- Object detection: This capability is essential for robots in manufacturing contexts. Annotation creates datasets that allow machine learning models to precisely locate the materials that they are required to manipulate.

- Environmental sensing: Robotic arms often work on crowded production lines characterised by fast movement. In order for automation to be introduced further AI powered robots must be able to identify objects and avoid them if necessary.

Bounding boxes train AI models to locate specific objects, such as large products or pieces of material. This capability allows AI robots to avoid collisions and prevent accidents. - Inventory management: AI can greatly improve the efficiency of inventory management. Automated robotic systems can identify inventory items and sort them without human supervision. Annotated images of inventory shelves form the basis of training material for this technology.

- Quality control: AI systems can also operate as additional eyes for quality control purposes. Machine learning can often help robots to spot defects that may not be visible to human operators. Bounding boxes help these models identify and locate objects.

Unlock annotation with outsourcing

Bounding boxes make a wide range of AI use cases possible. In the manufacturing sector image and video annotation are helping to streamline production processes and improve product quality. In order to access effective data annotation many AI companies are reaching out to providers like Keymakr. Doing so allows them to take advantage of some key strengths:

- Precision: Keymakr ensures pixel-perfect accuracy in all annotation techniques by leveraging an in-house team of skilled annotation professionals. This contrasts with some annotation crowdsourcing methods which can be of varying quality due to a lack of management and oversight.

- Cost: Creating a data annotation operation can be costly for AI companies, due to staffing and computing expenses. Outsourcing allows data production to be increased when needed, but scaled back when development timelines change.

- Quality control: For models operating in potentially dangerous environments quality image and video data is essential. Keymakr’s annotation platform and QC processes guarantee that mistakes will be caught before they reach important datasets.

Keymakr is creating exceptional image and video training data for manufacturing and robotics innovators. Contact a team member to book your personalized demo today.